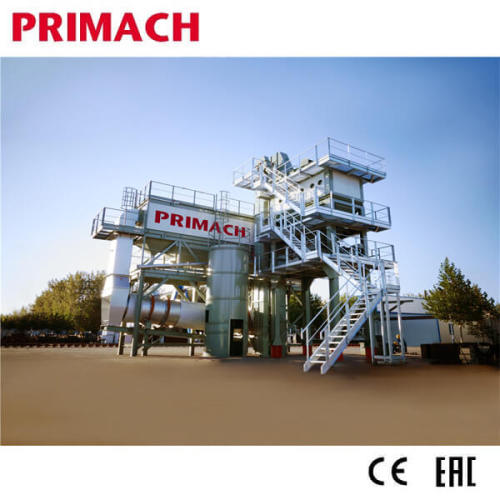

PM60-240 CLASSIC Stationary Batch Type Asphalt Mixing Plant

- Model

- PM60-240

Item specifics

- Capacity

- 60-240/H

- Fuel

- Oil / Natural Gas / Coal

- After service

- 7x24 special service team

- Emission

- Ringelmann Blackness Class Ⅰ

- Place of production

- Langfang city, Hebei, China

- Brand

- PRIMACH

- control system

- PLC

- Dust collector

- Primary gravity+Bag filter

Review

Description

Product Introduction

The stationary batch type asphalt mixing plant is the most popular type among all types of asphalt plants. PRIMACH stationary asphalt mixing plant is design in top quality to ensure the best performance and price ratio. Besides that, The MMI of control system is easy to study and operate. It is also known for its reliability.

The asphalt mixing plant Classic is the ideal choice for not only highway construction but also for other freeway maintenance task. As one of the leading manufacturers and a total solutions provider in the asphalt mixing plant industry, PRIMACH is capable of provide customized service according to the actual demands of clients.

SPECIFICATION

MODEL-CLASSIC |

PM60-240 |

|

Rated Production Capacity |

60-240 t/h |

|

Cold Feeder Bin |

4 m³x4 6.5m³ x 4 6.5m³ x 4 8m³ x 4 or 5 8m³ x 5 or 6 10m³ x 5 18m³ x 5 |

|

Dry Drum Size | Ø 1.2m x 5.2 m Ø 1.5m x 6.5 m Ø 1.8m x 8 m Ø 1.9 m x 8 m Ø 2.0 m x 8.5 m Ø 2.2 m x 9 m Ø 2.5 m x 9 m | |

Dust Collector | Primary gravity+Bag filter | |

Filter Area | 280㎡ 380㎡ 420㎡ 450㎡ 600㎡ | |

Screen | 4 4 4 4 or 5 5 or 6 | |

Mesh Area | 8.7㎡ 14.88㎡ 14.88㎡ 13㎡ 20㎡ 24.2㎡ 38.4㎡ | |

Hot Bin Volume | 6.9 m³ 18.2 m³ 18.2 m³ 14 m³ 20 m³ 21 m³ 45 m³ | |

Mixer Capacity | 700kg 1100kg 1300kg 1550kg 2000kg 2000kg 3300kg | |

Control System | PLC | |

Emission Rank | ● Dust Density ≤ 50 mg/Nm³ ● Cabin Noise ≤ 70 dB ● Ringelmann Blackness Class Ⅰ | |

Note: ● Some specifications / options might not be available in some countries due to local regulations. ● Specifications / options are constantly updated and subject to change. | ||

Product Features

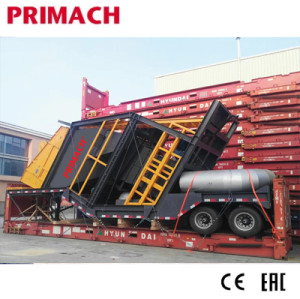

1. Modular design

The asphalt mixing plant Classic is designed in modular concept, we considered about the cost of sea freight and relocation chance in practice case. Every module of the equipment is designed in SOC or can be put into 40 feet's container. For transport locally, every module of plants can be taken by a 16m trailer.

2. Wide capacity range

We provide full range to satisfied various demands. The specifications of PM60-240 Classic are from 60 to 240t/h

3. The most reliable components

For assure the stable and service life of asphalt plant, we select the most famous brand for key components supplier. There are ROSSI Motor Iduttori, SIEMENS, NSK, WAMGROUP, ABS and others prestigious world supplier in our supplier group. PRIMACH always keep pace with the international advanced technology.

4. Smart control system

PRIMACH asphalt mixing plant Classic adopts own development “Leap” PLC control system. With friendly MMI interface, operator can be easy to study and work. The system is equipped with remote control system. Once get authorized PRIMACH can connect to the site to diagnose and analysis the working condition remotely.

5. Compact

Considering the site space and energy consumption, PRIMACH apply in the compact concept during design process. For example, we integrate the handrails and ladders with mix tower together, and place the bag filter on the top of the drum to save space.

6. Cost effective energy solutions

PRIMACH provide multiple option burners. Customer can choose Diesel, heavy oil, gas, coal powder as the burning material.

PRODUCT DISPLAY

Application