Retrofitting& upgrading

- Share

Why retrofit?

Not every country's economic situation encourages businessmen to make heavy investment in replacing their asphalt plants. Nowadays, with plant revision, it is possible to make an existing plant competitive even when compared to the most modern sites. Therefore, with limited investment, the company can be competitive and maintain, or even increase, their share of the market.

Upgrading = immediate economic returns.

WHAT IS RETROFITTING?

Retrofitting in the world of asphalt plants is a self-explanatory word which covers all the operations of renewing dated equipment, prolonging its useful working life and increasing plant performance. Retrofitting consists of adding new solutions to existing plants, replacing obsolete or dated technologies with new solutions and also giving new life to parts which need replacement while still reutilizing the plant parts which still have a valid life span.

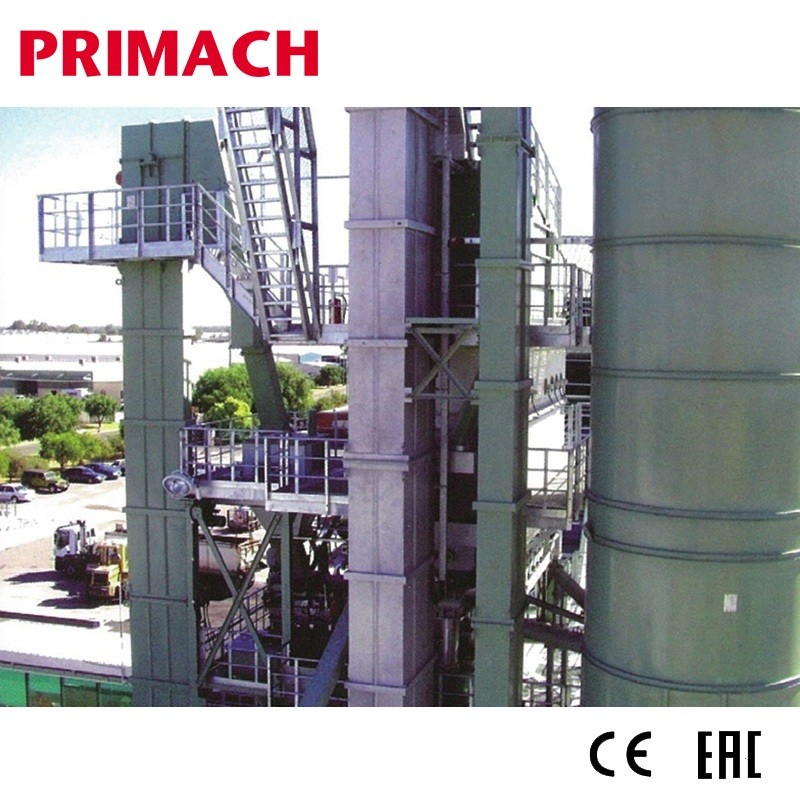

Retrofitting in PRIMACH – not just upgrading

PRIMACH offers its clients the experience and professional experience of a dedicated team capable of offering solutions and consultancy on:

1. Renewing old plants by integrating new components

2. Increasing plant efficiency

3. Boosting plant output

4. Upgrading plants to new standards, regarding emissions and the environment

5. Adding kits and solutions to get the best use out of RAP

6. Implementing the most up-to-date technologies for cold asphalt production.

Our team of experts and consultants work closely together with our clients to identify the best solutions which offer reliability and quick return on investment.

The most requested retrofitting on the market

Our retrofitting team can boast a series of successful interventions. Complex sites and made-to-measure solutions have led to PRIMACH living up to all expectations, satisfying even the most demanding clients. In addition to these special situations, there are also a series of more simple interventions, which the market continues to demand with a certain amount of frequency:

1. Up-dating hardware and software

2. Up-grading the plant on the basis of new safety laws and regulations

3. New bag filters

4. Producing special new dryer drum models

5. Implementing modern solutions for producing warm asphalts

6. New fuels for newer, more modern burners

7. Renewal of bitumen parks

8. New cold feeders

9. Replacing mixing tower

10. Enlarging storage capacity of finished product

11. Implementation of new solutions for RAP use (recycling ring, cold feed in mixer, double drum)

Retrofitting on competitors'plants

It would be wrong to claim that this activity is limited only to plants manufactured by PRIMACH . Many clients who own competitors'plants have turned to MARINI to up-date and improve their plants, taking advantage of the experience and skills of our specialists.

PRIMACH is one of the pioneers in developing asphalt recycling plants. It has full range of 10 - 50% of RAP and various types of eco-friendly asphalt recycling plant with high-end configurations. The product designs adopt the international standard and are in line with the specific requirements of working conditions in user's countries.

RAP Feeded to Mixer Directly:

RAP feeder —> RAP elevator —> RAP surge hopper —> RAP metering and weighing-mixer

20% RAP added-RAP Feeded to Mixer Tower Through Elevator for asphalt mixing plant for sale

RAP Feeded to Mixer Tower Through Elevator:

RAP Feeder —> Metering Belt Conveyor —> Elevator —> Mix Tower (Screening — Weighing — Mixing)

35% RAP added-RAP Ring Upon Drum for asphalt recycling plant

RAP Ring Upon Drum:

RAP Feeder-Metering —> Belt Conveyor —> Ring Upon Drum —> Elevator —> Mix Tower(Screening-Weighing-Mixing)

50% RAP added-RAP Drum with regular asphalt mixing plant design

RAP Drum:

RAP feeder-RAP drum-RAP surge hopper-RAPmetering-mixer